The Timer Box and Bezel

Having a huge, glowing, red countdown timer was always going to be a key feature of the mod. These things only seem to exist in the movies, after all, if you were planting something like this you are unlikely to care about sticking around to see just how many seconds are left on the clock! The timer for WMD serves a dual purpose - to provide a nice visual effect, and as something that can be used at a LAN event. Imagine arriving at an event, working out how many hours and minutes until the end, and setting the timer to count away until the event finishes. Every time someone walks past WMD, they'll know exactly how many hours of gaming goodness they have left!

The actual timer I will be using was the

first thing I acquired for the project, and will be shown in a later article (when it gets installed). It will end up fully controllable by a keypad, and able to be locked to prevent 'tampering'. I also have a few ideas on other functions that I can tie into the timer. Anyway, first it needs a home:

The steel for the timer box was laser-cut, folded and welded together. I gave it a pretty good polish and ground the welds smooth. The box was designed to be open at the back to allow me to drill holes and openings in the case to run cables through. The small shelves along the top and bottom provide a way to anchor it to the case, and a way of fixing the front bezel on. I had the front bezel there with me, while the box was being made, as it allowed the fit to be checked to ensure they both matched.

Here you can see the curves that were pre-cut into the sides. They match the radius of the curve of the main cylinder and will enable the box to sit flush to the case. A piece of masking tape gave me a surface to mark a centre-line on.

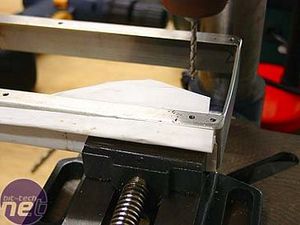

I'd already drilled 8 holes in the strips at the back for the front bezel screws, and tapped them to M4 threads. Now I marked and drilled another 6 holes in order to fix it to the cylinder.

Once the holes were drilled...I used the box as a template and marked the cylinder...

...before drilling corresponding holes in the cylinder. Despite being *only* 2mm thick, the stainless steel is so tough (and under tension from having been rolled) that I had to put the case on the floor in order to use most of my body weight to push down on the drill to get through it. There was quite a bit of marking out and measuring done to get the timer exactly centred and square to the case. You can see it sits just above the line of fasteners that (when the case sits correctly) mark the centre-front of the cylinder. This puts the timer on a slight upward angle, making it easy to read from sitting or standing near the case, plus leaving room for some things that I'll be mounting below it.

A quick test-fit of the timer bezel..

Fitting the Bezel and Timer Box

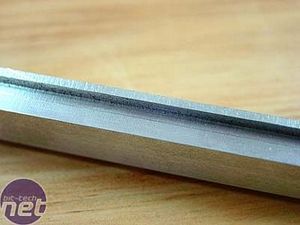

For the timer bezel I wanted something a bit special. With a lot of the visual focus of the mod likely to be on the display, it needed more than just a flat piece of steel or plexi. I decided to dig deep and shell out the $$ (rather painfully as it turned out) to get something CNC milled. It looked like I was going to have to get it milled from Aluminium, as stainless steel would be too hard to mill and would, alone, have cost more than the rest of the case and everything in it! Aluminium would be plenty strong enough for the bezel, my biggest concern being how well the colour of the Aluminium was going to fit with that of the stainless steel.

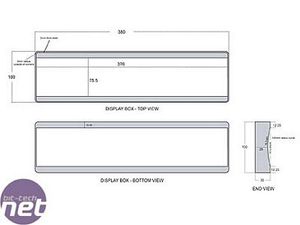

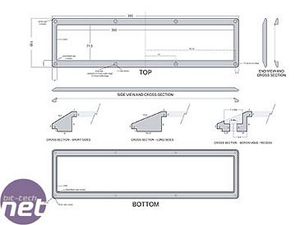

First, I drew up mega-detailed drawings of the bezel with every possible measurement, then I sent these off and waited. The bezel came back and I was suitably impressed with the result.

The angled sides and rounded corners came out well, as did the recessed screw-holes.

I'd even worked in a recess for the top edge of the timer box, and a lip to retain the plexi cover.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.